VIBRIO M offers everything you need

To start your functional predictive maintenance

Automatic mode and 3-button control

Highly appreciated by beginners

Automatic mode FASIT©

Easy to use and no knowledge or experience required!

1. Just initiate automatic machine fault detection.

2. You obtain an instant on-screen traffic light alarm indication

of:

Bad bearings, Unbalance, Misalignment and Mechanical

looseness.

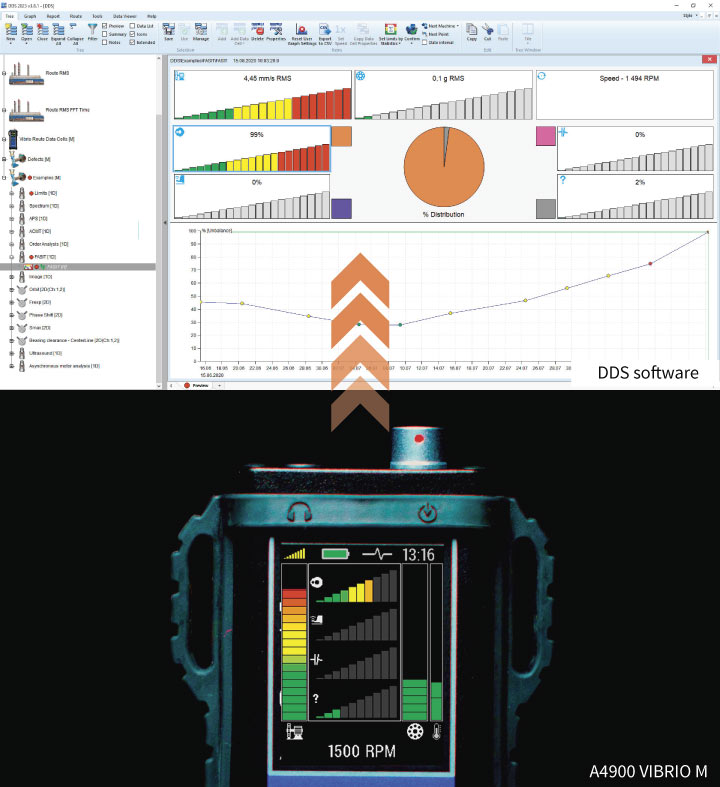

3. The severity of all detected defects is then trended in the DDS software.

Automatic mode

Plug and play

Rugged and tough

Easy to use

STORE, TREND, ANALYSE

-

Collect & import vibration data

Vibrio M along with free DDS software is the easiest way to begin your predictive maintenance program based on machinery condition.

Make your route VIBRIO M measurements regularly and send the new vibration data to DDS (Digital Diagnostics System). Follow vibration trends and observe the actual condition of your machines. -

Collect vibration data easily - create your ROUTE

Create a scheme of your machinery park in DDS, define measurement points on particular machines and set up appropriate measurement types which you want to take. Send this route to Vibrio M and let yourself be guided by VIBRIO M.

-

Trend the vibration data

Follow the vibration trends of your machinery. Setup alarm and danger vibration limits and using traffic light colours, be notified in case of any change.

-

Analyze the vibration data

Get to know the Adash expert system FASIT and use our special analysis features to make your life easier. DDS software allows you to make deep analysis of your vibration data. Play with Overall values, FFTs, Time waveforms, Orbits and many more. Use various cursors, zooming, display options. Switch on bearing fault frequencies from a database of over 30000 bearings or define your bearing.

![vibration analyst adash vibrio]()

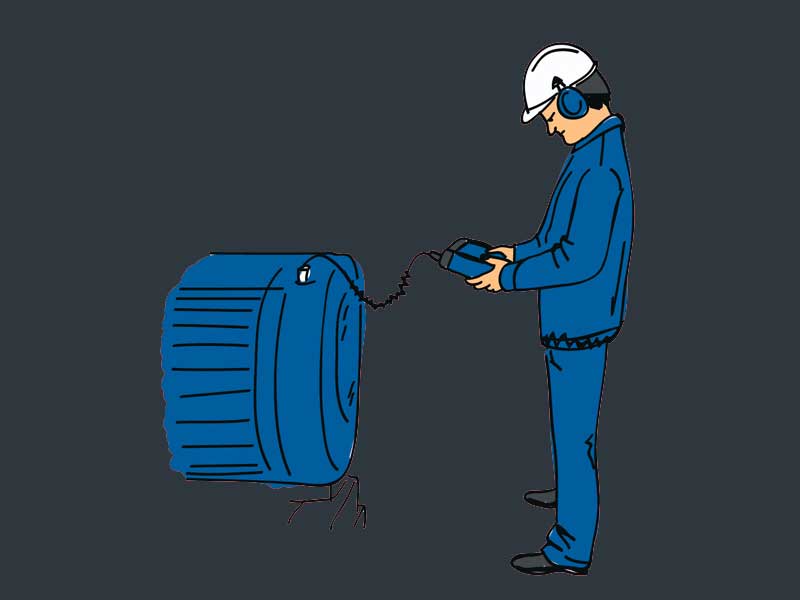

MEASURING VIBRATIONS UNDER THE SAME CONDITIONS

Collect reliable vibration data

-

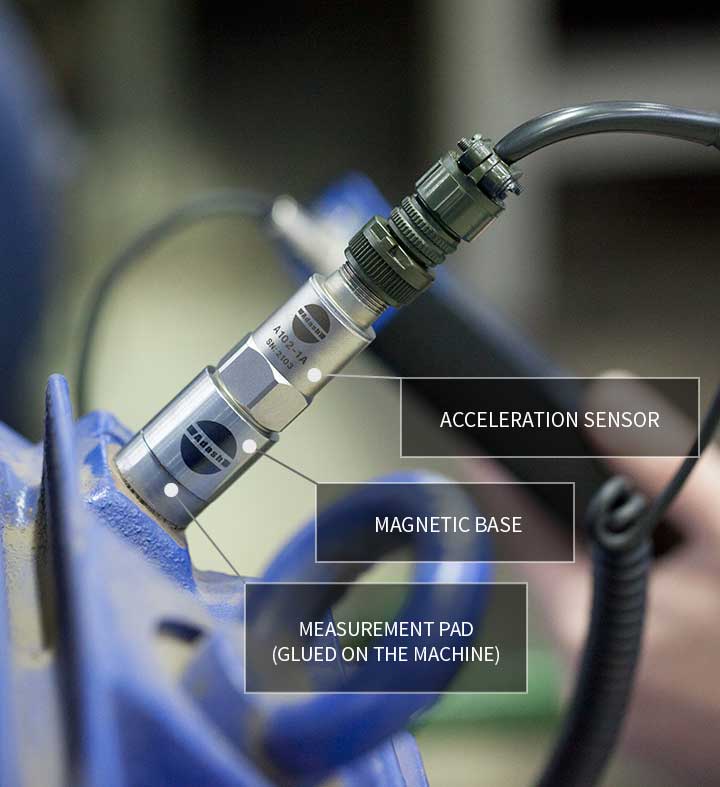

Measurement points on the machine

Firstly, you must define the measurement points on the machine. It is good to use one point for each bearing in the radial direction i.e. perpendicular to the shaft and one point on the axial direction. For horizontal shaft use the direction between the horizontal and vertical axes. For vertical shafts use any radial direction.

For a standard machine like a motor + fan, you get 5 points. -

Preparation

of

measurement points

The next step is the preparation of measurement points. Good preparation ensures repeatability of measurements. It is a key factor for vibration analysis. It is critical mainly for bearing condition measurement. The standard way is to use pads. They are glued to the machine and ensure the correct signal transmission path to the sensor. The readings are repeatable and this property is very important.

When the sensor is mounted to a surface which is not flat, then it swings and the measured value also swings.

When the sensor is mounted to a pad, then the value is stable. You can take the first readings once you have prepared your points.![Sensor Vibration analysis]()

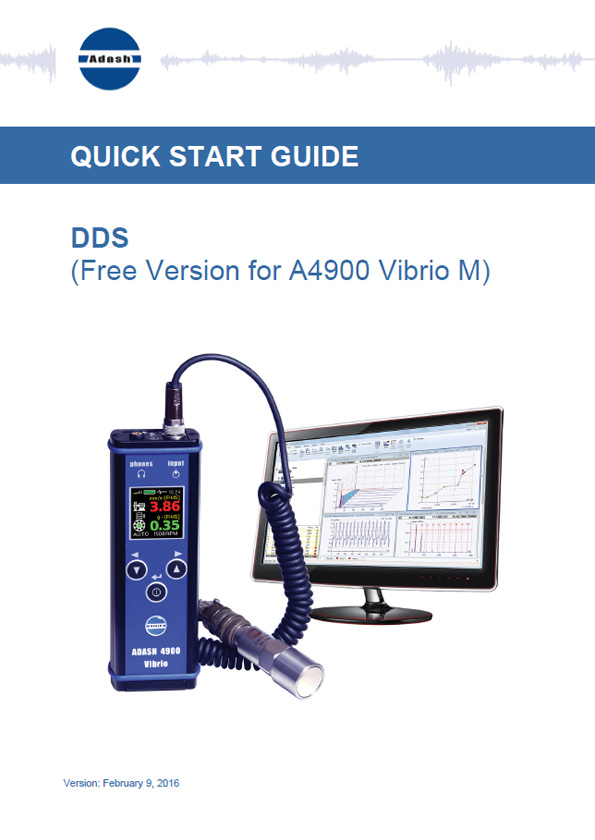

4900 VIBRIO M - functions

-

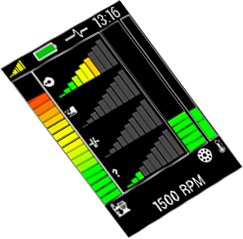

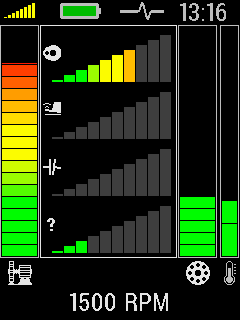

Automatic fault detection system - FASIT ©

Expert System FASIT - Automatic machine fault detection.

Direct indication and severity of Unbalance, Looseness, Misalignment and Bearing condition.

This system enables you to directly measure fault severity based on vibration. The vibration data is the input, and the fault severity diagnosis is the output. You can save the data to the DDS database and then view fault severity trend graphs.![A4900 Vibrio Fasit]()

-

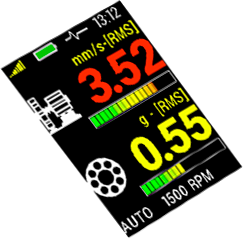

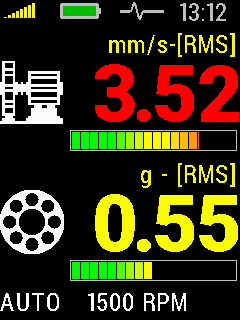

Overall values - RMS

Velocity for whole machine body vibrations

Acceleration for bearing vibrationsAutomatic speed detection

![A4900 Vibrio overall values rms]()

-

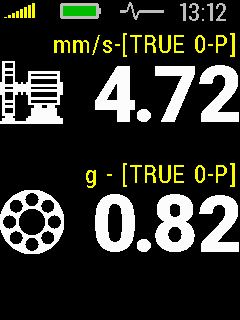

Overall values - PEAK

Velocity for whole machine body vibrations

Acceleration for bearing vibrations![A4900 Vibrio overall values peak]()

-

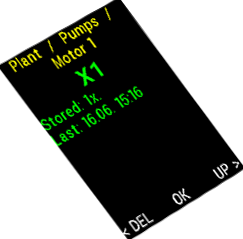

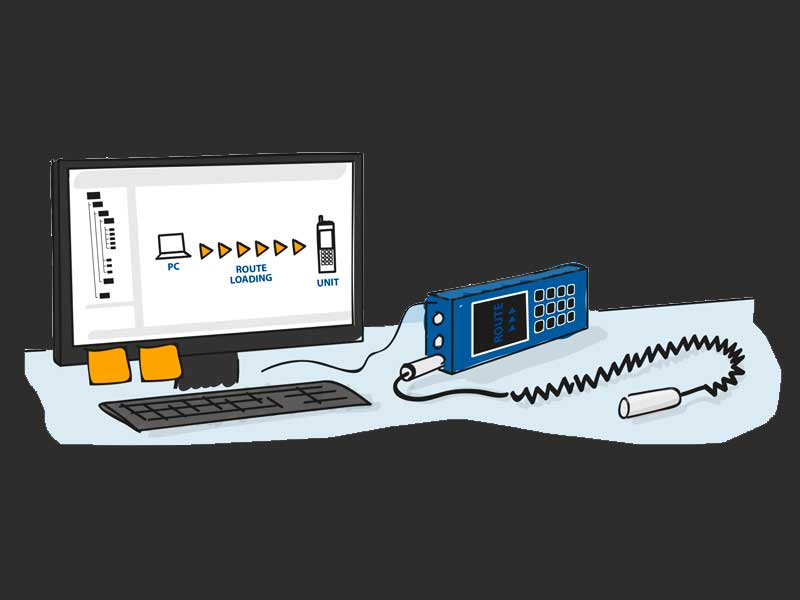

Route

A tool for quick and easy data collection from your regular machinery park measurements.

Create a scheme of your machinery park in DDS, define measurement points on particular machines and setup appropriate measurement types which you want to take. Send this route to VIBRIO M and let yourself be guided on your route by VIBRIO M.![A4900 Vibrio Route]()

-

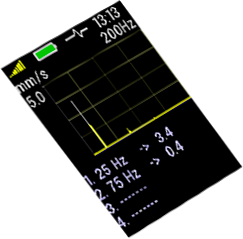

Spectrum

FFT analysis of vibrations

3 max peaks detection![A4900 Vibrio Spectrum]()

-

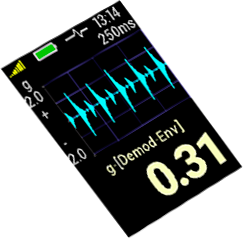

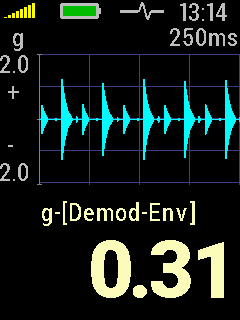

Time signal

Time waveform for a bearing shocks observation

Demodulation – Envelope value![A4900 Vibrio Time Signal]()

-

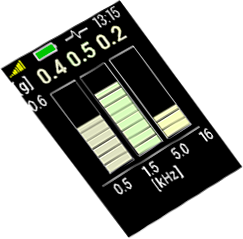

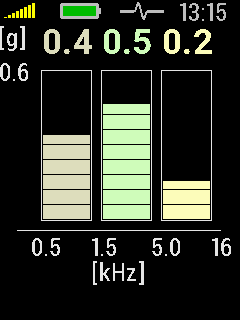

Frequency bands

3 frequency bands for highest acceleration signal detection

![A4900 Vibrio Time Frequency bands]()

-

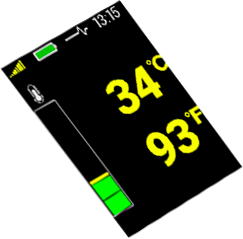

Temperature

Contactless temperature measurement in degrees Celsius and Fahrenheit

![A4900 Vibrio Time temperature]()

-

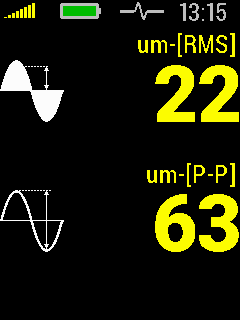

Displacement

Overall RMS and Peak measurement of vibration displacement

![A4900 Vibrio Time Displacement]()

-

Autosave

Automatic data logger and small online system

Select the measurement you want to take, define time interval between readings and start continuous data collection.![A4900 Vibrio Time autosave]()

16 hours of operation

free software

IR thermometer

stroboscope + torch

VIBRATION TREND EVALUATION

-

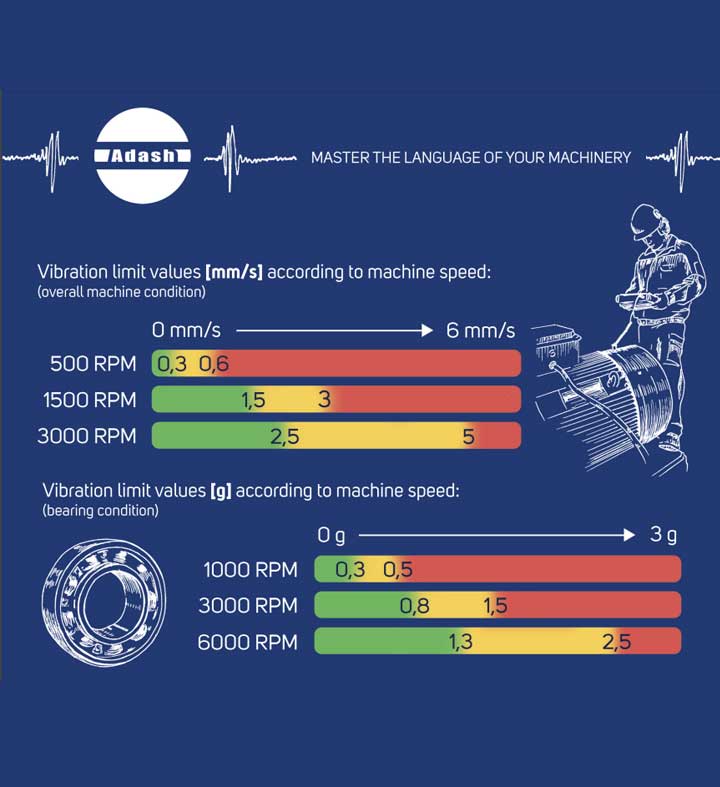

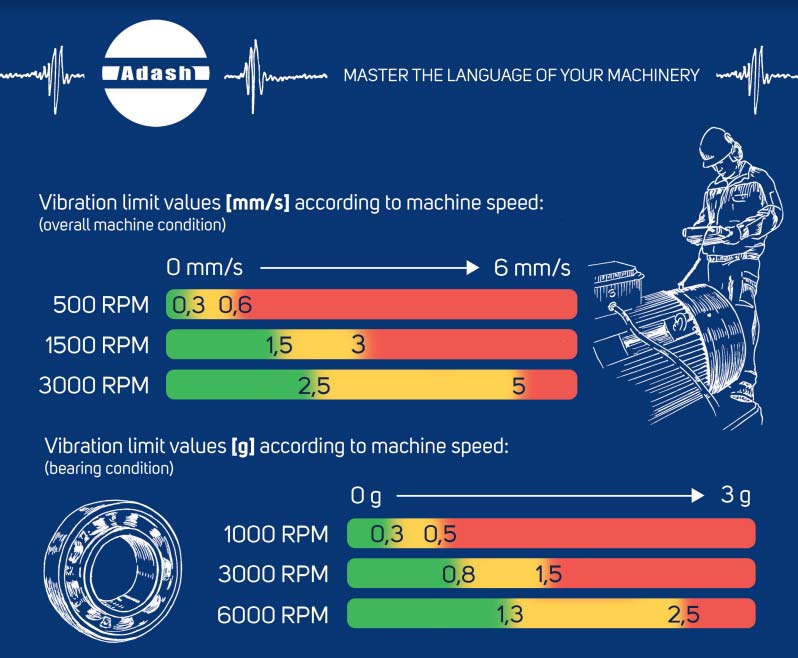

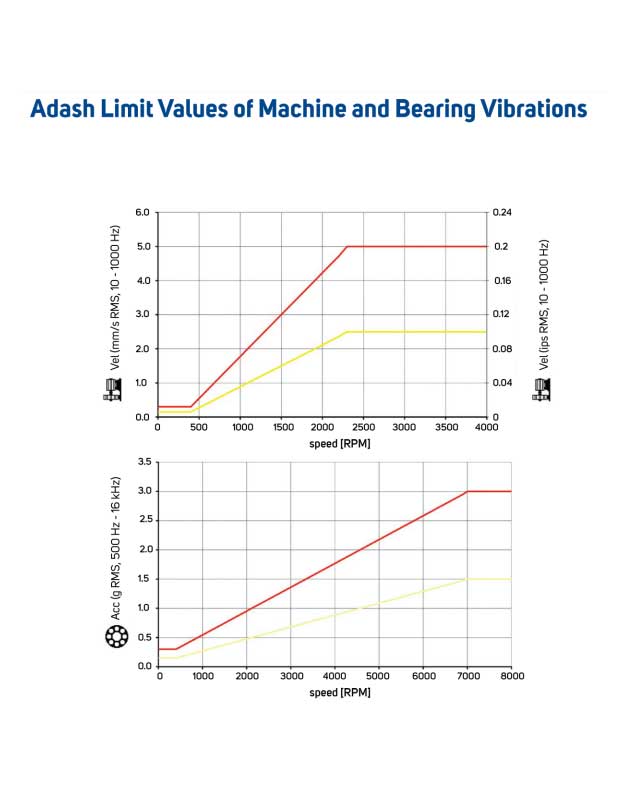

ADASH Limits

Based on 30 years of experience in the field we have developed easy and clear system of vibration limits usable for wide variety of machinary operations and reflecting its own specifics.

![adash vibration limits]()

-

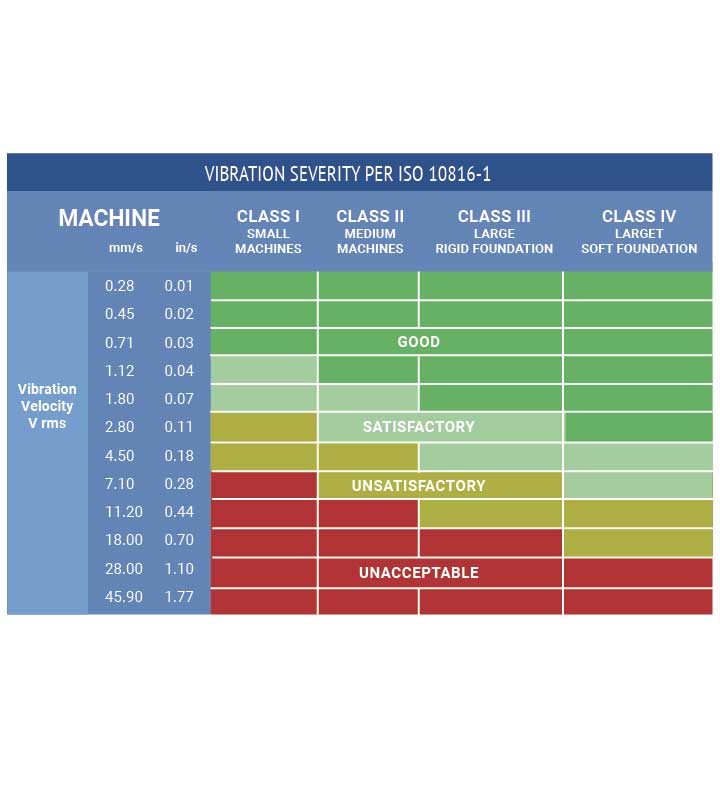

ISO 10816 limits

World-wide standardised limits.

![adash iso 10816]()

-

Overall velocity measurement

This type of low frequency vibration measurement cover all mechanical faults which are related to the speed of the machine such as unbalance, misalignment and mechanical looseness.

-

Automatic fault detection system - FASIT ©

The automatic fault detection system FASIT enables you to directly measure machine fault severity based on vibration. Fasit indicate the severity of Unbalance, Looseness, Misalignment and Bearing condition. The vibration data is the input, and the fault severity diagnosis is the output. You can save the data to the DDS database and then view fault severity trend graphs.

![adash iso 10816]()

-

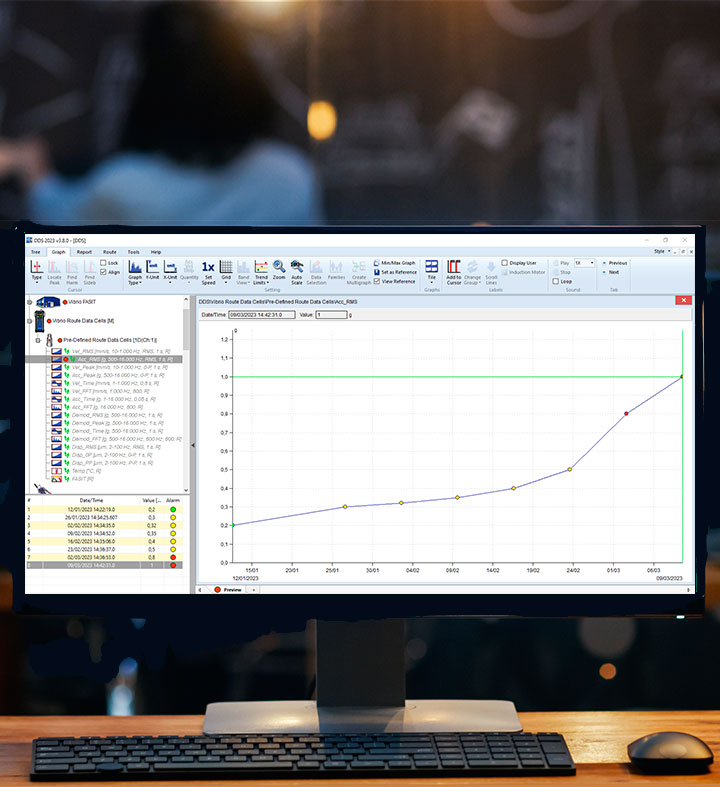

Overall acceleration measurement

This type of high frequency vibration measurement covers condition of the bearings.

![DDS acceleration RMS graph]()

-

Vibration SPECTRUM

This is the view of each frequency component of the measured overall vibration. It allows you to see dominant frequencies and therefore deduct the source of vibration.

KNOWLEDGE BASE

-

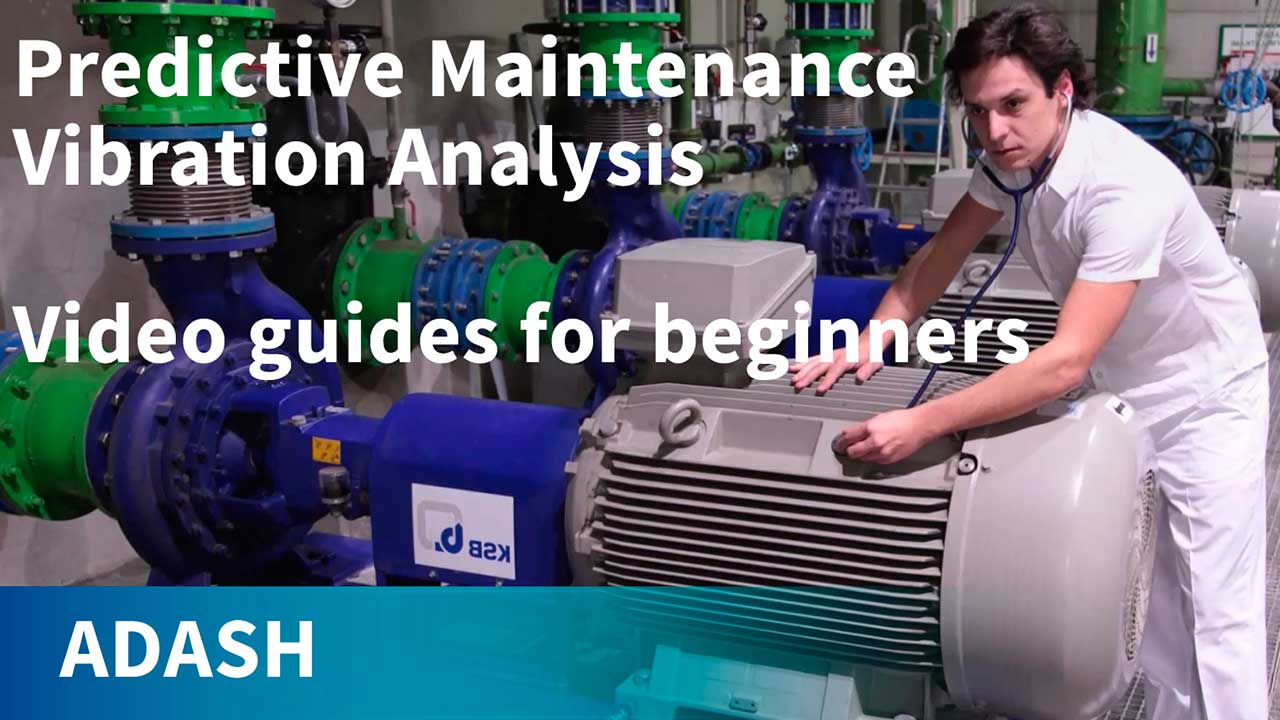

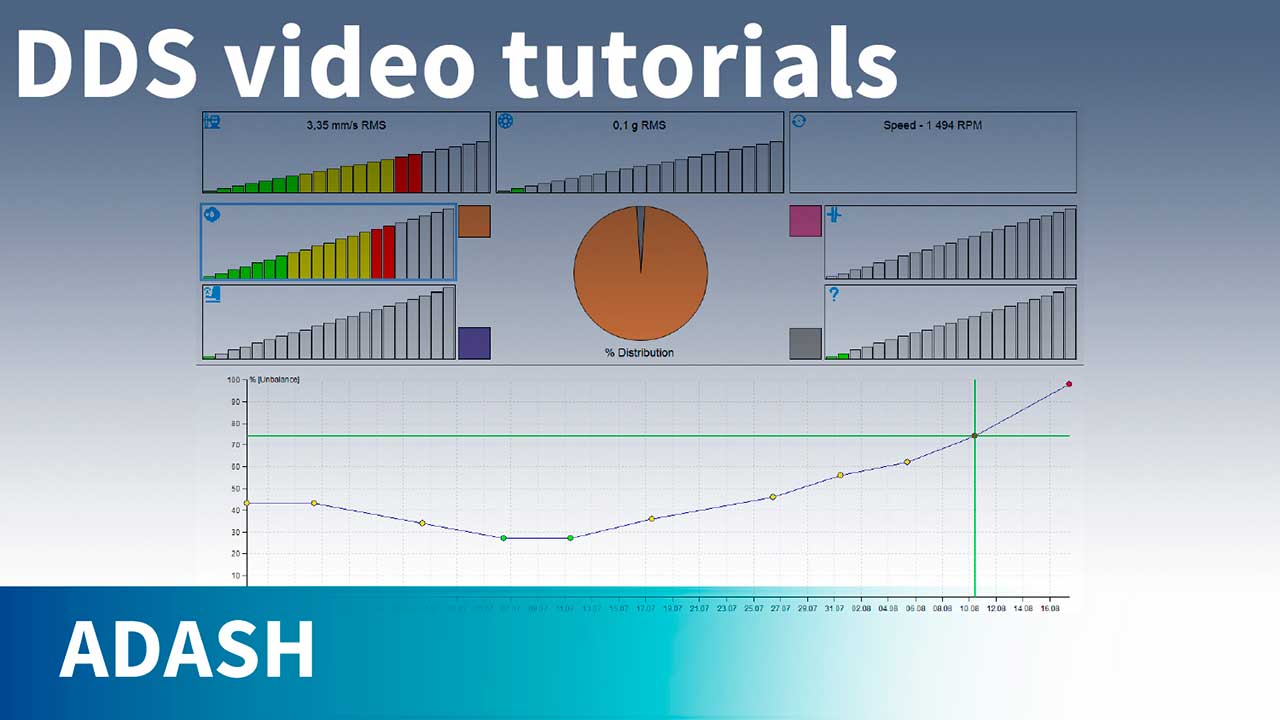

Video guides

Our videos will explain everything needed for predictive maintenance in an easy-to-understand way.

-

Step by step Predictive Maintenance guide

All information you need for Predictive Maintenance implementation

-

Manuals

Vibrio MDDSADASH Vibration Limits Values

Adash Ltd. offers tools and software for predictive maintenance and vibration analysis to all kinds of customers according to their needs and budget. We want our customers to actively benefit from the features offered by our products instead of leaving our tools on the shelf.

MORE PRODUCTS